Rapid 3D Printing of Lenses

Thursday, April 12 2018 | 00 h 00 min | Vision Science

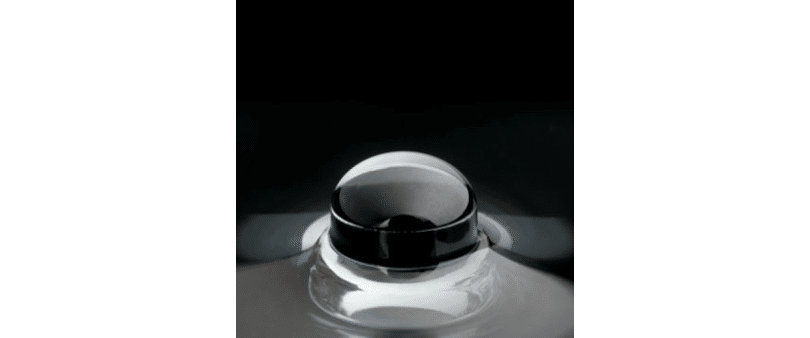

A method of using a 3D printer to rapidly create small aspheric lenses offers new possibilities for manufacturing customized contact lenses and optical imaging lenses.

Developed by a team at Northwestern University Engineering, the layer-by-layer 3D printing technique is capable of creating a 5 mm in diameter lens in about four hours. The lenses have less than 7 nanometre surface roughness, which means that the standard step of polishing the lens can be omitted.

“Up until now, we relied heavily on the time-consuming and costly process of polishing lenses,” said Cheng Sun, associate professor of mechanical engineering and lead researcher on the project. “With 3D printing, now you have the freedom to design and customize a lens quickly.”

Adding additional transition layers between steps and and treatment with a photocurable resin resulted in a smooth, transparent lens.

“We realized that the layers on top of each other created surface roughness. The layer thickness is typically 5 microns, while the wavelength of visible light is around 0.5 micron. This creates an optically rough surface,” explained Sun. “That was the bottleneck. The roughness made the lens incapable of clear optics.”

The group’s next goal is to expand their method to larger lenses and creating customized contact lenses for keratoconus patients. “The contact lens would feature the customized surface, matching it to the shape of the patient’s cornea,” Sun said.

Their work was published in the March 27 edition of Advanced Materials.